Steel Structure

Cranes

Metal Fabricaiton

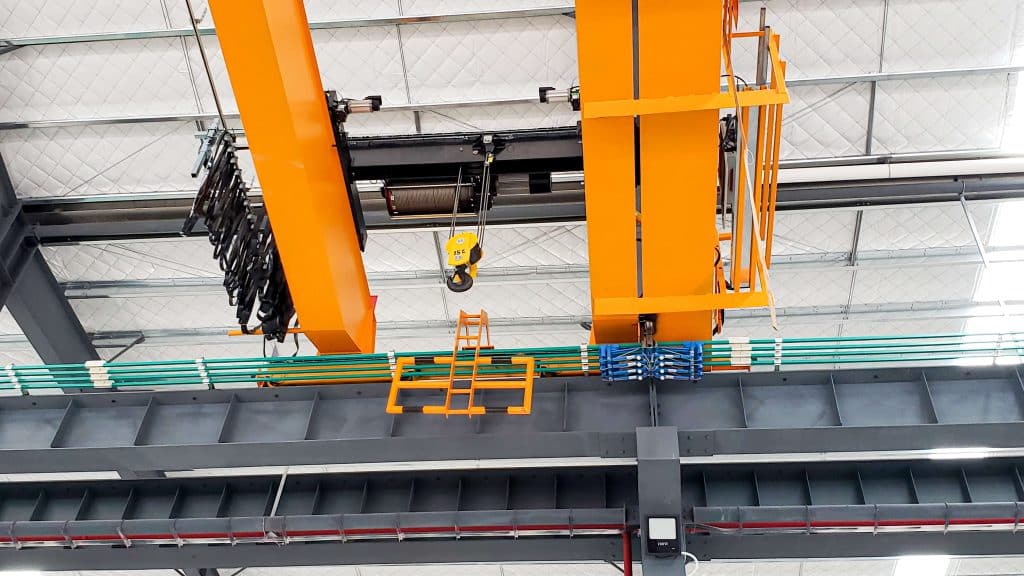

Crane Runway Systems

The foundation of any effective overhead crane system lies in its runway. This structural support system includes beams, columns, and rails, pivotal for material handling operations. Depending on your crane configuration, we provide solutions for both top-running and under-running cranes, ensuring your structure can support the necessary load, be it through tied-back columns or independent free-standing columns.

Crane Runway Systems

The team at Guanhui provides comprehensive support for all your crane runway system needs, whether you are:

- Planning a new runway solution.

- Verifying the integrity of your current runway system for a planned expansion.

- Integrating another crane into your existing runway.

Guanhui professionals can also assist with new facility planning by providing comprehensive reports and in-depth analysis of your current or proposed runway system. Let Guanhui be your single source for all your material handling and runway requirements.

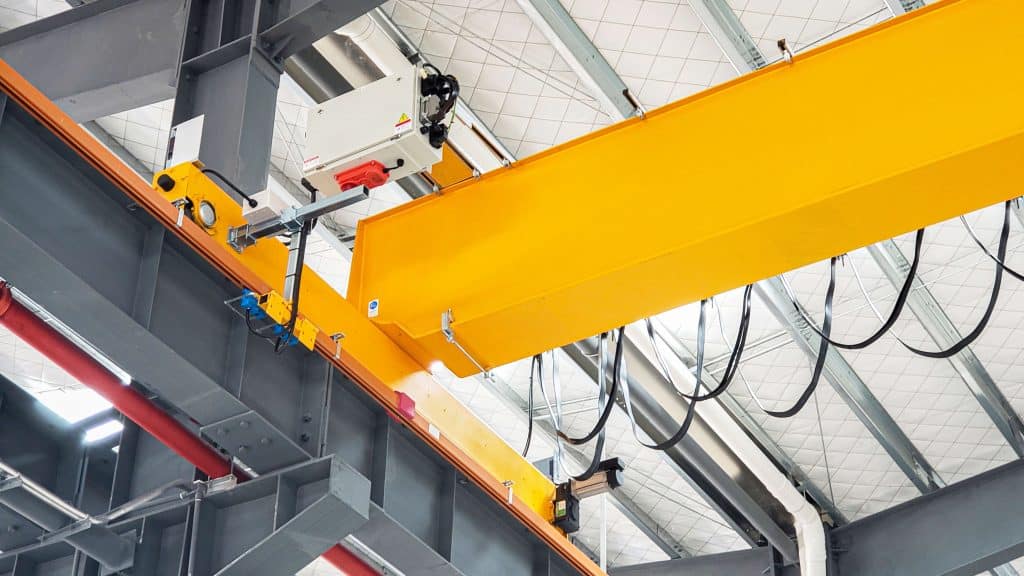

What Is a Bridge Crane Runway?

A bridge crane runway system is the structural backbone of your material handling solution. It comprises the beams, columns, and rails upon which the crane operates. Bridge or girder end trucks travel along the rails, which are securely fastened to the runway beams. These beams are typically supported by building structures in one of two primary configurations:

- Top Running: Runway beams are mounted to columns.

- Under Running: Runway beams are suspended from the roof structure.

When integrating a new crane into an existing building, it’s crucial to assess the capacity of the existing columns. They must be capable of supporting the combined load of the new crane and runway. If necessary, new columns can be installed:

- Tied-Back Columns: Connected to the existing building structure for added support.

- Free-Standing Columns: Independent structures separate from the building.

Tied-back columns offer an effective, practical, and safe method for enhancing lateral support to the crane runway.

When you need a new runway or modifications to an existing one, Guanhui’s experienced team will thoroughly analyze your operational environment and application requirements. Based on this analysis, we recommend a runway solution tailored to your specific demands and the constraints of your facility. Guanhui runway systems are economical, designed with safety as a priority, and certified by our in-house engineers.

How We Can Help:

- Runway Design: At Guanhui, we believe the engineers who design your crane should also design your runway structure. Our structural and mechanical engineers use CAD systems to create runway designs that strictly adhere to crane standards, Uniform Building Code, and steel welding standards and practices.

- Runway Fabrication: The same robust quality standards applied to our cranes extend to our runway structures. Often, the same skilled craftspeople and welders who fabricate your crane also produce your runway system.

- Runway Installation: A properly installed runway is essential for a smooth-running crane system. Our experienced installation teams are runway experts with a proven track record across numerous projects, ensuring quick and efficient installations.

- Self-Installation Support: Alternatively, you can fabricate and install the runway yourself. We provide guidance and support to help you troubleshoot any challenges you may encounter.