Steel Structure

Cranes

Metal Fabricaiton

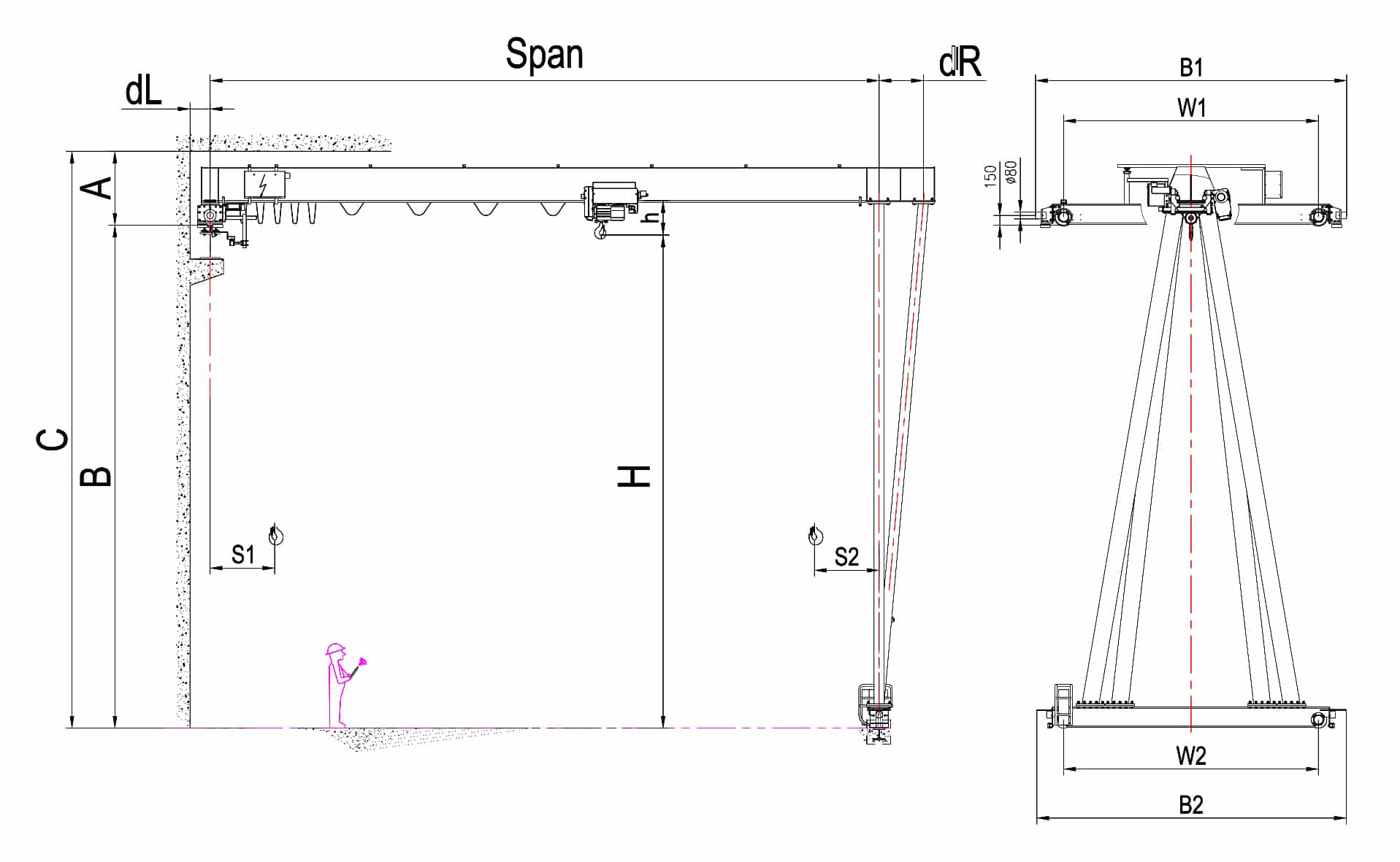

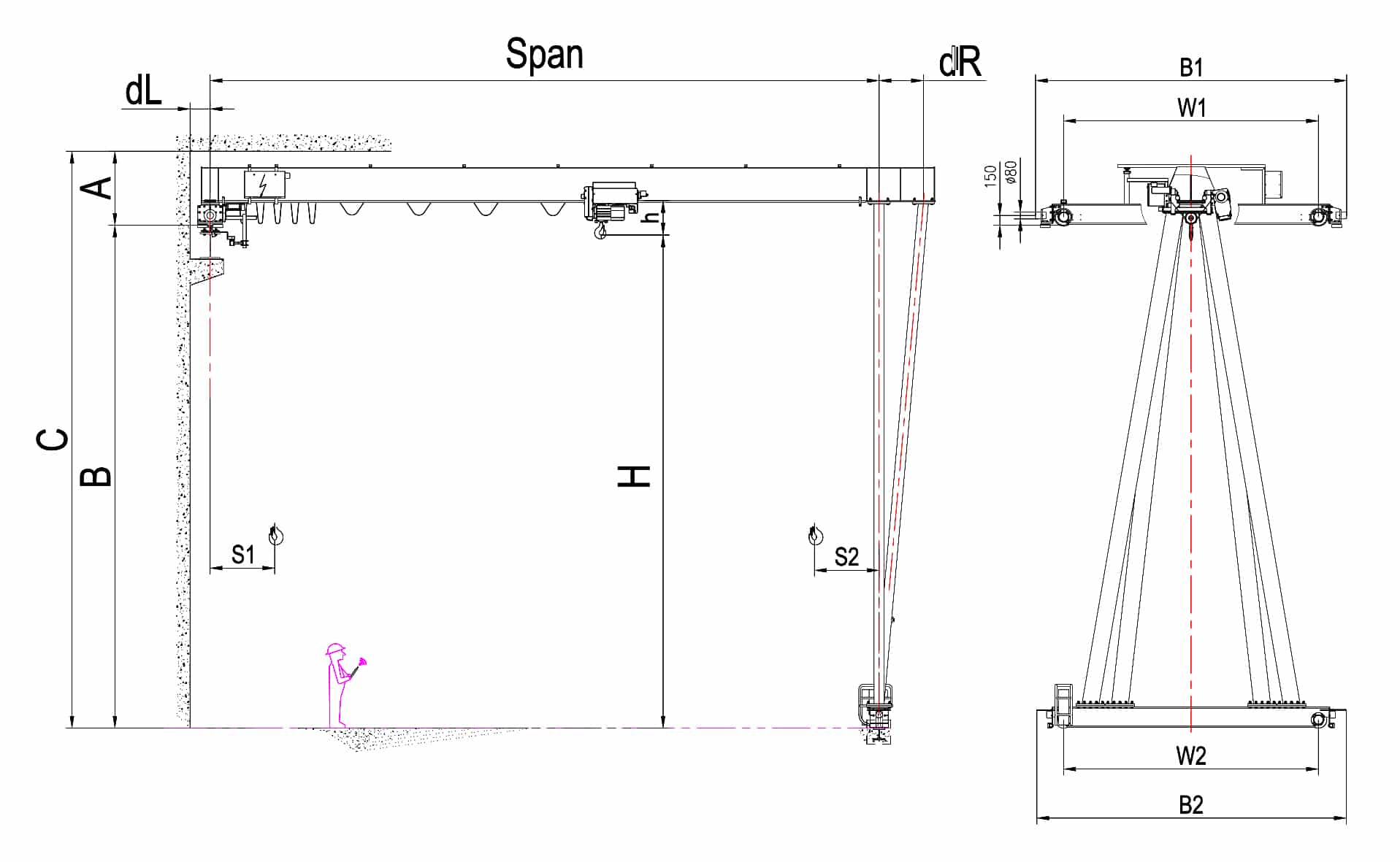

BM Semi-gantry Crane

The BM Semi-Gantry Crane is a reliable and efficient lifting solution designed for both indoor and outdoor applications. This versatile crane is available in single or double beam configurations and is ideal for a wide range of industrial tasks, including light to heavy-duty operations. With advanced safety features, energy-efficient components, and customizable options, it ensures high performance and reliability.

Why Choose Guanhui’s BM Semi-Gantry Crane?

Guanhui specializes in delivering customized semi-gantry crane solutions tailored to your unique operational requirements. Our cranes offer significant advantages, including:

- Flexible Capacity Range: Available in single girder models (2–20 tons) and double girder models (5–80 tons), ensuring suitability for various lifting needs.

- Extended Span Capabilities: Span lengths up to 50 meters, providing maximum operational coverage and flexibility.

- Innovative Rail Configuration: Combines on-floor rails with elevated rails, enabling seamless integration and flexible operation beneath existing overhead cranes.

- Space Optimization: Ideal for localized hook services, production cells, and specific bay areas, effectively utilizing space beneath existing crane structures.

- Enhanced Safety Features: Integrated advanced safety systems, including wind speed anemometers, anti-collision devices, and storm anchors, ensuring smooth and safe operations.

Customized Semi-Gantry Crane Solutions Tailored for Your Facility

Guanhui’s BM Semi-Gantry Cranes offer extensive customization options to meet your specific lifting needs:

- Optional Cantilever Extensions: Extend operational coverage and enhance flexibility for off-center loading and material transfers.

- Multiple Control Systems: Choose from pendant, remote control, or operator cab systems, providing optimal operational convenience.

- Advanced Safety Systems: Equipped with comprehensive safety features like anti-collision systems, wind speed anemometers, and storm anchors to ensure safe crane operation.

- Flexible Power Supply Options: Powered or non-powered cable reeling drums, conductor bars, or festoon systems available to suit your facility’s requirements.

Key Specifications of BM Semi-Gantry Cranes

- Lifting Capacity: Single girder (2–20 tons), Double girder (5–80 tons)

- Span Length: Up to 50 meters

- Rail Configuration: Combination of on-floor and high-level rails

- Control Options: Pendant, remote control, or cab operation

- Safety Equipment: Anti-collision systems, wind speed anemometers, storm anchors

- Power Supply Options: Cable reeling drums (powered/non-powered), conductor bars, festoon systems

Industries Served by Guanhui BM Semi-Gantry Cranes

Guanhui’s semi-gantry cranes are trusted and widely used across various industries, including:

- Manufacturing Plants

- Construction Sites

- Shipyards and Ports

- Mining and Heavy Industries

Why Trust Guanhui for Your Semi-Gantry Crane Solutions?

Guanhui is a globally recognized crane manufacturer known for reliability, innovation, and exceptional customer support. Our BM Semi-Gantry Cranes provide:

- Custom Engineering: Tailored crane solutions designed specifically for your operational needs.

- Proven Reliability: Successfully deployed across diverse industries worldwide, ensuring dependable long-term performance.

- Comprehensive Support: From initial design and engineering to installation and ongoing maintenance, Guanhui provides end-to-end service and local expertise.

Choose Guanhui’s BM Semi-Gantry Crane for efficient, space-saving, and reliable lifting solutions tailored to your operational needs.